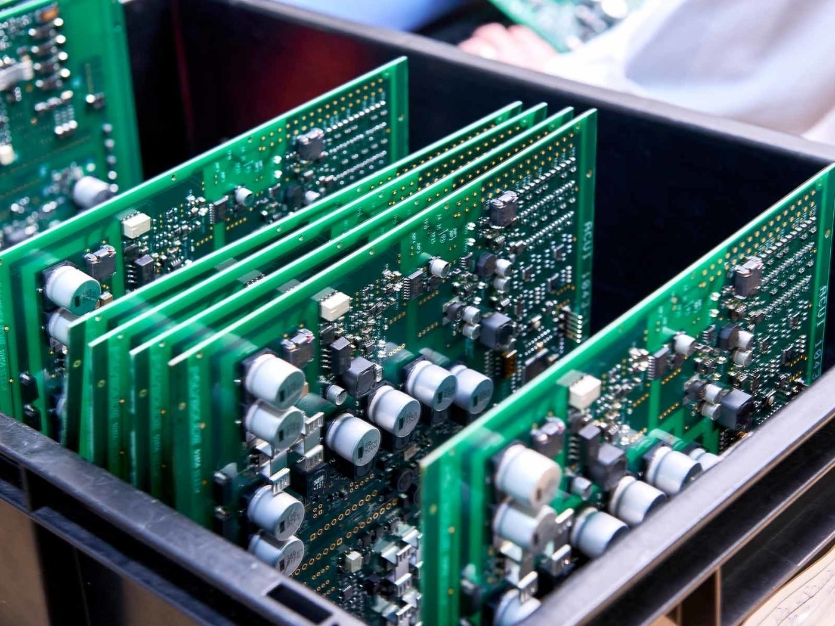

Component assembly:

multiple processes

Cofidur SEICO’s production includes boards made from surface-mounted components (SMD) as well as conventional through-hole components, or a combination of both.

Soldering is carried out using a lead-free process (in compliance with the ROHS directive), with automated visual and X-ray inspection.

Among its tools

manufacturing, Cofidur SEICO

account:

– 3 latest-generation Europlacer automated SMT lines (ATOM3, IINEO and Vitesse 2) with a production capacity of 40,000 components per hour;

– 2 automatic screen printing lines;

– 2 reflow furnaces;

– 1 soldering waves (ROHS);

– Ability to work 3×8 shifts.

The test tools consist of:

– 1 2D X-ray machine;

– 1 TAKAYA APT 9411 mobile probe tester;

– 2 MIRTEC automatic optical inspection (AOI) machines.

For an optimum end

product

– For optimum protection of boards and electronic systems, tropicalizing varnish and coating are used on request.

– In addition to the initial checks, electrical tests are carried out to check that all connections operate properly. They are coupled with functional tests designed to validate the match between the expected result and actual performance.

Functional test benches can be developed by Cofidur SEICO or supplied by the customer with the procedure to be followed. We can couple these electrical tests with our Rapid Temperature Change (RTC) ovens to detect any teething problems.

– After delivery, diagnostics andany repairs to boards and electronic systems are carried out by the after-sales service. Our teams can also use our VRT ovens to detect intermittent failures.

– For maintenance in operational conditions (MCO) of products in use, an active obsolescence watch enables us to react and propose equivalent solutions.